Comments (0)

Written by: Federico Aleotti (ENGIE Equatorial), Tunmise Raji (Rochester Institute of Technology, NY), Mercy Nthenya Kyatha (University of Massachusetts Amherst, MA)

Publishing date: November 2022

Part 4: Lessons learned

Introduction

This article is part of a series of articles intended to disseminate learnings and outcomes of a e-mobility pilot on Lake Victoria, carried out by ENGIE Equatorial, a joint venture between ENGIE, an international low carbon energy and services company, and Equatorial Power, a mini-grid developer based in Kampala. ENGIE Equatorial has deployed a hybrid solar mini-grid on Lolwe Island (Lake Victoria, Uganda), ensuring energy access to 3800+ households and businesses in the local community.

An e-mobility pilot was also implemented to assess the techno-economic feasibility assessment, and social and environmental impact assessment of the deployment of such technology within the fishing community on Lolwe. A total of 15 electric outboard (e-outboard) kits were deployed to replace an equivalent number of Internal Combustion Engines (ICE) outboards powered by gasoline.

This e-outboards pilot received funding from the PREO programme, which is co-funded by the IKEA Foundation and UK Aid via the Transforming Energy Access platform.

ENGIE Equatorial partners with STIMA Lab of the University of Massachusetts (UMASS) Amherst that will provide support on data collection, data analysis and results dissemination. By sharing the experience, ENGIE Equatorial intends to support similar projects and other developers to accelerate the global transition towards a more-sustainable, low-carbon mobility.

Lessons learned

1.Performances of the system and equipment sizing

As elaborated in more details in the first article [1], the results of GPS data analysis show that power demand, and thus energy demand, changes significantly with cruise speed.

The most accredited tests showed that reducing the cruise speed by 15% (from an average of 13.6 to 11.6 km/h), resulted in energy saving of around 50% (from 0.441 to 0.232 kWh/km). This means that the fishermen can double the coverable distance (or halve the battery bank capacity needs, depending on the point of view) by simply slightly reducing the speed whenever possible. Considering that the battery bank plays a big role on the overall kit cost, this aspect has implications for the return on the investment.

The electric power needed by the boat is around 3-4 kW in normal lake conditions, but it is advisable to consider a contingency oversizing for the adverse weather conditions. This considered, it was observed that the engine sizing of 6 kW met the required performances. Some fishermen expressed the need for e-outboards with higher rated power. However, when comparing GPS data collected of 10 HP ICE and 6kW e-outboards, it was noted that these looked generally equivalent in terms of speed. A possible explanation to these few customers’ feedback could be the different perception that the user has of the speed, as the ICE engine gets very noisy when pushed at high rounds per minute, while e-outboards remain relatively silent. It is then possible that the perception of speed might be influenced by the vibration and noise heard. In any case, this aspect should be investigated further.

Regarding the battery bank sizing, 8 to 9 kWh rated capacity ended up being a good compromise between short and medium trips. Clearly, different customers have different needs, so it is recommended to use battery modules of around 2 to 4 kWh, that can be added in parallel to ensure extra coverable distance when needed. It is worth noting that the specific weight (kg per rated kWh) and specific volume (m3 per rated kWh) tend to increase with smaller rated battery modules. This means that, at a given total storage capacity, the total volume and weight increase with multiple smaller batteries.

2. Maintenance requirements

Most of the existing ICE outboards have large availability of spare parts, which usually share the same characteristics. Furthermore, most of the mechanics on the islands have acquired a comprehensive know-how on maintaining and fixing these outboards. In the authors’ experience, e-outboards require less maintenance than ICE motors. However, when a fault occurs on an e-outboard, there is little experience on how to repair it as it is a new technology. In particular when considering batteries, manufacturers discourage users from tampering, due to high risks of electric shock, short-circuits and potential damages. Generally opening a battery implies a warranty loss, but at the same time in most cases the manufacturers/suppliers do not have presence in Africa, and thus are not able to provide support on site or replacements. In this regard, there is a need for the manufacturers to extend their presence to the continent to ensure that the equipment can be serviced and maintained.

Regarding general maintenance, electric outboards also introduce new electronic components that can expose to new categories of faults for which local final users cannot troubleshoot. In this sense, availability of spare parts is also a crucial aspect. In particular tillers and propellers have shown to be more subjected to damages.

3. Design of existing outboards on the market

The use of outboards for fishing activities places more strain on the devices that would be experienced with normal recreational applications, and the fishermen indicated the need to have more durable e-outboards. Manufacturers that want to address this type of market are suggested to avoid the use of plastic parts (specially on the tillers), increase mechanical strength and robustness of the outboard body, and consider operations under extreme weather and lake conditions. In this regard, some cases of moisture infiltration were reported following exposure to rain, even though some of the equipment were rated IP67.

The design should also make the system easy to repair by a local mechanic with materials available on site, as already largely happens with wheeled vehicles. The cost and lifetime of the e-outboard are two of the most significant barriers to the adoption of this technology, so engines and batteries should be designed to last long and be easy to maintain.

The most common damages reported were (i) the propeller and fins break due to the presence of stones and rocks underneath the water, (ii) propeller being caught between fishing nets which then block the rotating shaft, (iii) loss of screws, nuts, levers and other small bodies connected to the engine, (iv) break or detach of both plastic and metal components, and (v) water and moisture infiltration in electronic components.

It was also interesting to observe that fishermen agree on the fact that metallic propellers, in their opinion, provide higher speeds than plastic ones. No analysis on performances has yet been done to verify whether data confirm this, or if possibly it is just a bias based on perception of the material strength.

4. Costs

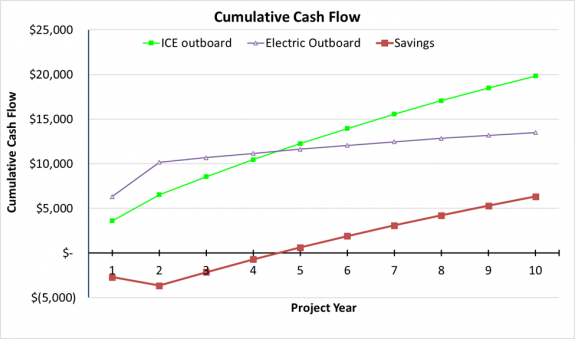

The experience gained showed that the e-outboard kit costs around 4 times a normal ICE outboard (6,500 USD vs. 1600 USD). This is a prohibitive price for most of the fishermen in the region. Several asset financing institutions are interested in knowing more about the technology and provide financing to local entrepreneurs. However, the uncertainty of the durability of the asset presents a significant risk for both entrepreneurs and financing institutions.

However, the operational costs for the final user should be significantly lower, estimated to around 46% according to a survey carried out recently with fishermen involved in the project [2]. It was therefore estimated that over the lifetime of the outboard, a fisherman on Lolwe choosing an electric propulsion system with a 2-year loan, might expect savings for about $6,328 over a 10 years’ time [2].

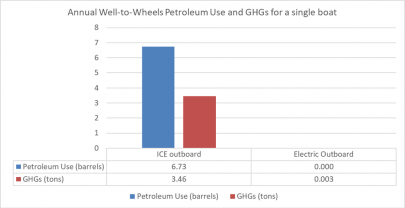

5. Environmental impact

The result of the analysis undertaken on Well-to-Wheels environmental impact [2] indicates a saving of around 3.46 tons of CO2 equivalent GHG for each boat per year. This means that assuming a 10-year operation of 15 outboards, the total GHG saving would be around 519 tons of CO2 equivalent.

6. Frequency of use

Usage influences the payback period of the investment as it is directly correlated with amount of fuel saved and, thus, number of fishing trips. Considering an option where the fishermen rent the outboards, we observed that the number of outboards rented is directly proportional to the seasonality of the fishing business. During low season, when fish availability is scarce and most fishermen return to the mainland, the number of outboards rented decreases significantly. This seasonality effect should be considered when choosing the business model and forecasting realistic cash flows. It was observed that the number of fishing trips that a boat does in a month can vary from 15 and 25 fishing trips per month, depending on the seasonality and fish availability.

Addressing other uses of mobility on the lake is an advisable strategy to decouple the e-outboards usage from fishing activities, and increase rentals and thus revenues, as for example local transport of people and goods from and to the mainland.

7. Community perception of the technology

This pilot represented the first example of electric outboards in Uganda. When the technology was first brought to Lolwe island, the fishing community welcomed it with a lot of interest and questions about economics and performances. In general, there was a high demand for show-off events to let people try them in first person. Some ambassadors were then selected to test the first engines and were the reference within the community for questions and feedback. Even though some scepticism is inevitable, a high demand of e-outboards emerged in a few months’ time, which gives good feedback of the product appreciation.

8. On-boat installation

The fishermen are used to removing the outboard every day, to prevent theft when the boat is not guarded. Therefore, batteries are recommended to be as small and light as possible. The threshold of around 30 kg was identified to enable one single person to carry a module. It is also recommended to install a specific enclosure where to mount the batteries, to protect them from sunshine and rain.

9. Battery charging infrastructure

On-boat charging was revealed to be more challenging that what was originally assessed, as boats usually dock to the shores front-headed, and this implies having cables running on the shore and dangerously hanging on water. Even adopting water-proof cables, the risk of damages to the outer insulation layer derived from day-to-day operations was considered not acceptable. For this reason, centralised charging station or private recharge was tested with generally positive outcomes.

Battery swapping is also a possibility; however, it was not tested in this specific pilot as it would implicate additional battery modules availability, with higher capital costs for the service provider. In case of multiple technologies used, compatibility issues between batteries and engine may arise.

From the energy source point of view, fishing activities take place at night, so batteries are charged only during the day. As proven in the Lolwe mini grid pilot, the energy demand from the grid is generally between 10 AM and 4 PM, thus in phase with solar PV generation. In this regard, the electric mobility for fishing applications was observed to be a consistent anchor load for the solar mini grid, as theoretically assessed by another study carried out on the Lolwe project [4].

References

[1] https://equatorial-power.com/uncategorized/e-mobility-for-fishermen-on-lake-victoria-part-1/

[2] https://equatorial-power.com/uncategorized/e-mobility-for-fishermen-on-lake-victoria-part-2/

[3] https://equatorial-power.com/uncategorized/e-mobility-for-fishermen-on-lake-victoria-part-3/

[4] J. Lukuyu, A. Muhebwa and J. Taneja, “Fish and Chips:Converting Fishing Boats for Electric Mobility to Serve as Minigrid Anchor Loads,” in In The Eleventh ACM International Conference on Future Energy Systems, Australia, June 22–26, 2020.